Electric Steam Superheater Design

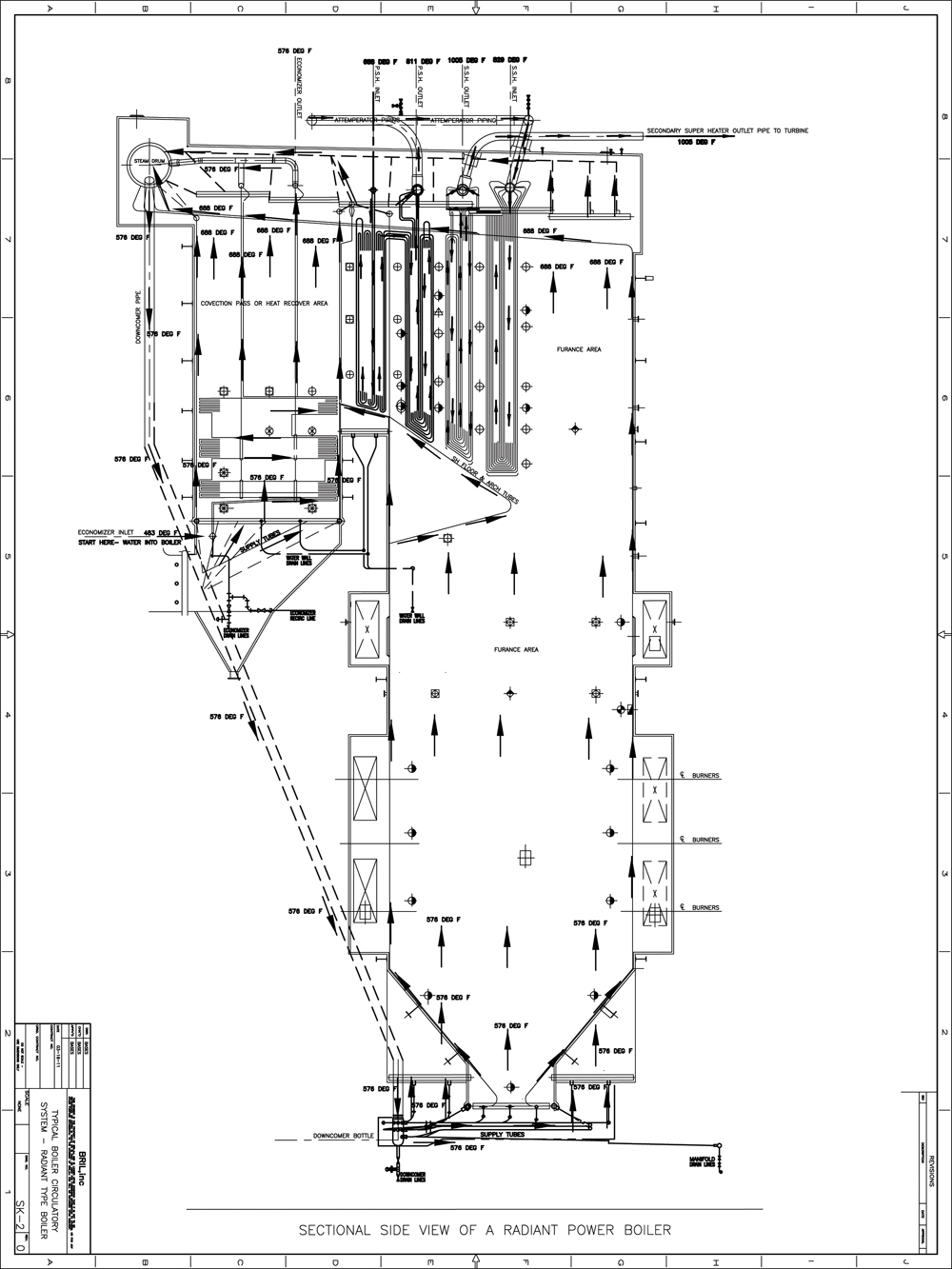

An alternative bottom supported design with the superheater reheater tubes growing vertically up in compression and carrying.

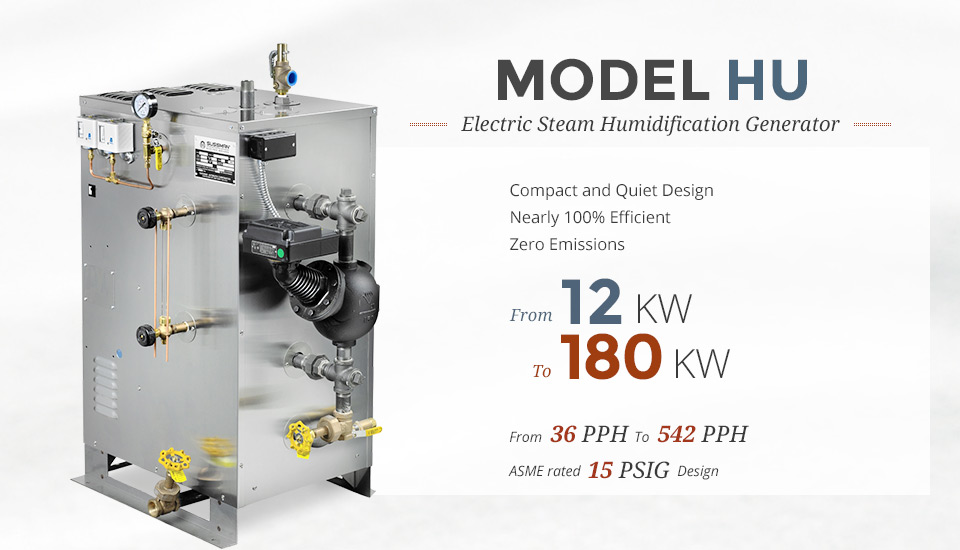

Electric steam superheater design. Standard range 200 1500 kg h steam at 1 barg up to 40 barg. The uniflux steam superheater can provide many advantages over competitive heaters. This means that. Large electric steam boilers.

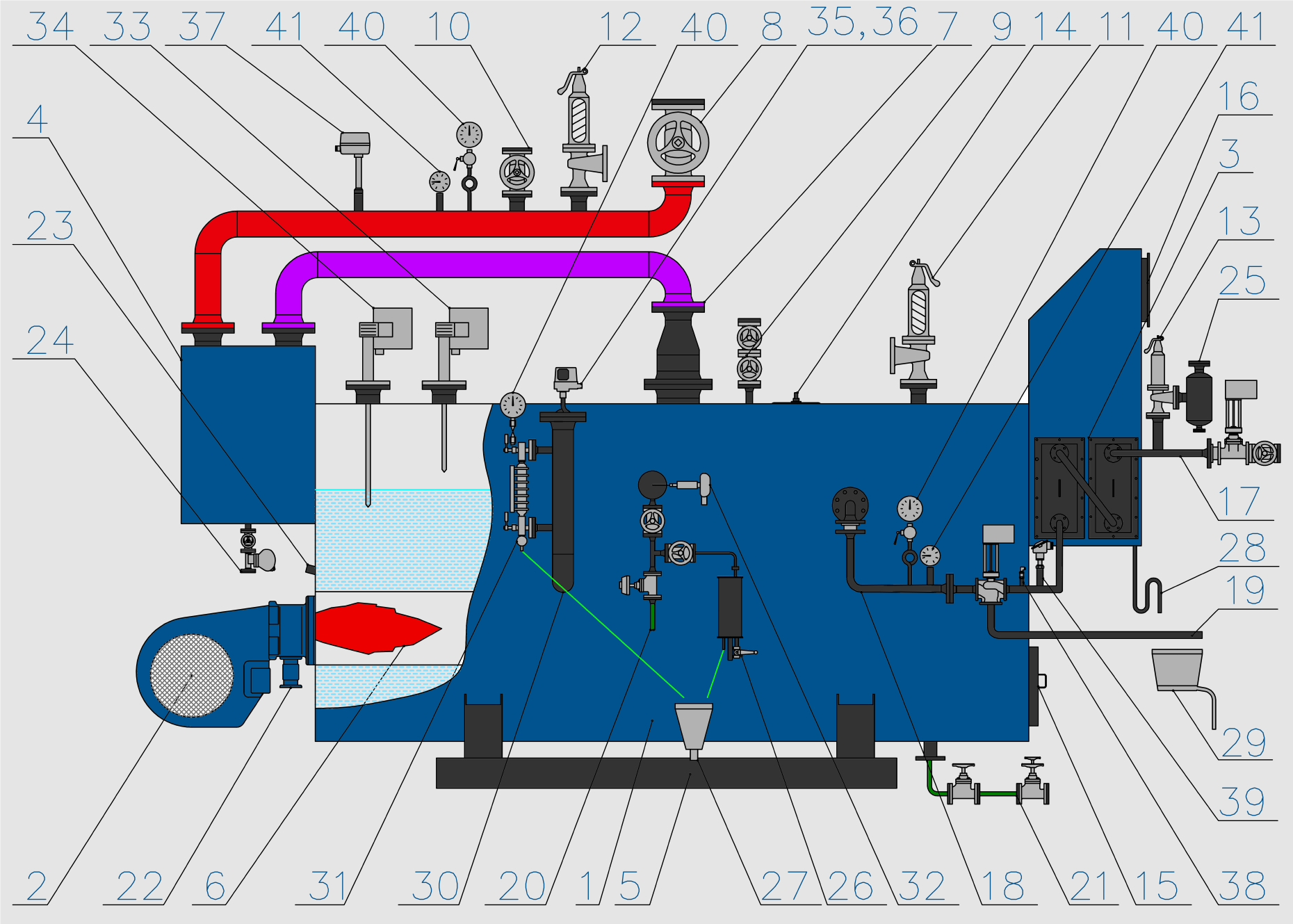

The flexibility in the helical coil design removes the higher coil stresses that are seen with serpentine coils that have hairpin type return bends. Coil type superheaters design generally consists of 180 o coils welded through the headers on both the sides. Compact design in a high quality design. Acme electric steam superheaters are available for use with steam boilers as an auxiliary piece of equipment.

Power generation the steam superheater aids in the drying of process steam. We manufacture our own electric steam boilers steam superheaters condensate return systems automatic blowdown systems heat tracing custom control systems and perform all skid design and manufacturing in house. Hennessey in heat recovery steam generator technology 2017. Superheaters and reheaters in horizontal gas flow natural circulation hrsgs are generally top supported allowing them to grow thermally down freely hanging in tension.

Our superheaters are manufactured according to the ibr regulations thermodyne manufactures both coil type and shell type superheaters depending upon the type of boiler and boiler capacity. Designed to your special heating requirements the sussman series ssh steam superheaters are suitable for the heating of saturated steam under pressurized conditions adding btu s to increase the quality and raise the temperature of saturated steam to match your process requirements. 6 3 8 bundle support types. Ssh electric steam superheaters.

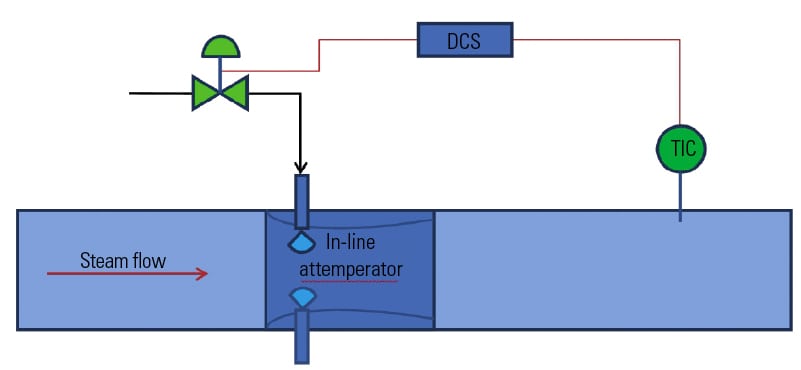

A superheater can vary in size from a few tens of feet to several hundred feet. In a coil type designs steam is inside the coil and flue. To maintain optimal performance of the system water vapor must be removed from the steam turbine system. 2 1 2 install steam piping connecting superheater steam outlet to equipment to be supplied with superheated steam.

Superheated steam is used in steam turbines for electricity generation steam engines and in processes such as steam reforming there are three types of superheaters. Pitch steam inlet piping to properly drain condensate formed in the steam line back to the boiler or to a trapped drip leg. A superheater is a device used to convert saturated steam or wet steam into superheated steam or dry steam. 2 1 1 install steam piping connecting steam supply to superheater inlet.

Radiant convection and separately fired.